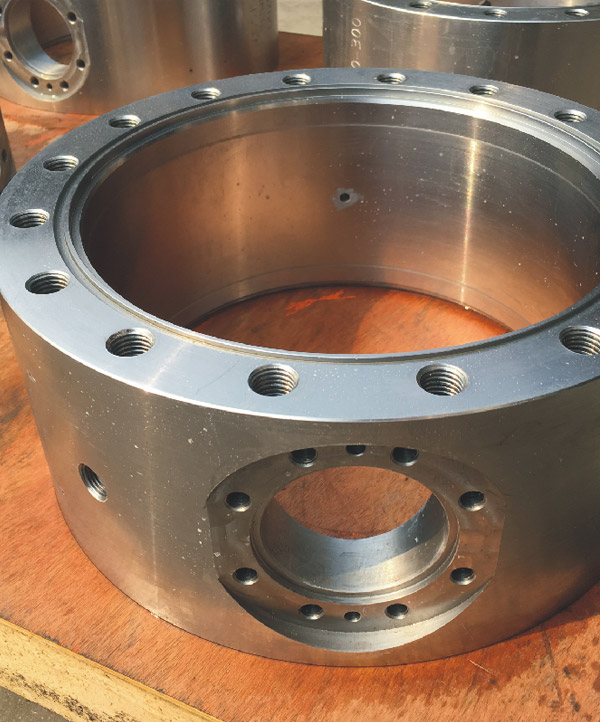

1. Technical requirements of the DIN Ball Valve Body

(1) After the seam welding, the valve body has no deformation, including the upper and lower shaft flanges (45 steel).

(2) The heating area of the valve body should not be too wide and the temperature should not be too high, otherwise the sealing device inside the valve body will be destroyed.

(3) No welds can occur.

(4) Ensure that the pressure is above 10 MPa.

2, weld structure

According to the above technical requirements, it is determined that the weld is not welded through the weld. Therefore, the butt joint form of the weld is required to ensure both assembly and penetration.

3, the material of the valve body

The chemical composition of the valve body from DIN Ball Valve Body Supplier was tested before processing, and the test results were consistent with the test results at the time of casting, meeting the design requirements.

4, assembly

The hydraulic tire is used to modify the reversing tire, and the two halves are fastened with bolts to adjust the sealing test, and the design between the outer part of the ball and the valve body is achieved.

5, welding process

Taking into account the technical requirements of the valve body, the MA2 CO2 welder was finally selected.

Previous: Applicability of Solenoid Valve Body